Membrane – three possible applications

by Fabian Hütter

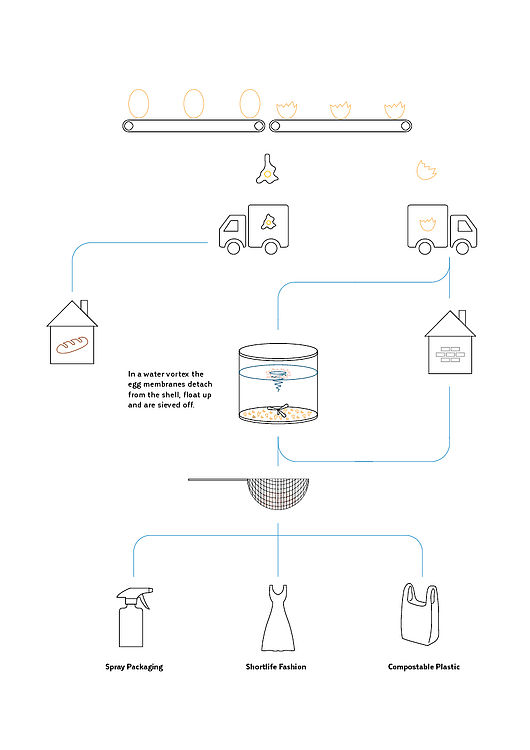

1.4 trillion poultry eggs are produced annually, according to the Food and Agriculture Organization of the United Nations (FAO). This corresponds to about 1.5 million tons of egg membrane. In the industrial context, the egg shells and membranes are used for cement production, but only the calcium carbonate (lime) of the egg shell is utilised. The glycoprotein egg membranes simply burn away. In order to save the valuable membranes, I developed a procedure to separate them from the shells. In the following I illustrate the potential of this material with three possible applications.

reuse

Semesterprojekt

Komplexes Gestalten, Sommersemester 2018

bei Prof. Mareike Gast, Anna Hoffmann, Karl Schikora

ab 3. Studienjahr Bachelor, ab 1. Studienjahr Master

Produktionsprozesse folgen oft geradlinigen Wertschöpfungsketten. Es entstehen ungewollte Nebenströme, Nebenprodukte – zumeist Abfallprodukte. Wir machten es uns in dem Projekt reuse zur Aufgabe, außergewöhnliche, überraschende, vielleicht skurrile, aber in jedem Fall wertvolle, industrielle Abfallströme ausfindig zu machen, und verwendeten diese als Ausgangspunkt – als Rohstoffe für ein neues Material, ein neues Produkt, ein System, das zirkulär funktioniert statt linear. Der Fokus des Projektes lag auf der explorativen und experimentellen Auseinandersetzung mit vielfältigen Materialien und deren Weiterverarbeitung sowie auf der Vernetzung verschiedener Industrien und Prozesse für die Entwicklung nachhaltiger Produkt- und Businesskonzepte.Mit Unterstützung von externen Partnern wurden Konzepte, Materialien, Services und Anwendungsszenarien für Abfallmaterialien entwickelt, die vernetzen und zirkulieren.

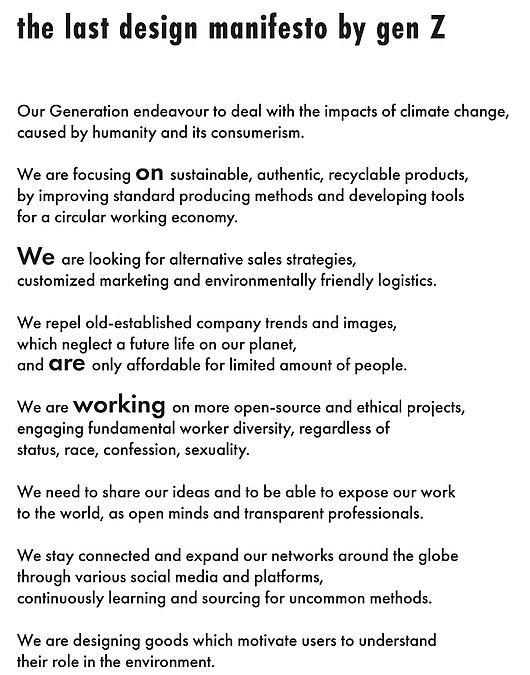

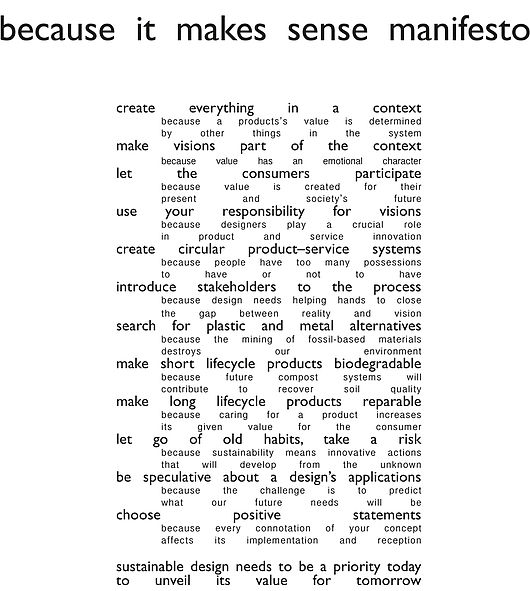

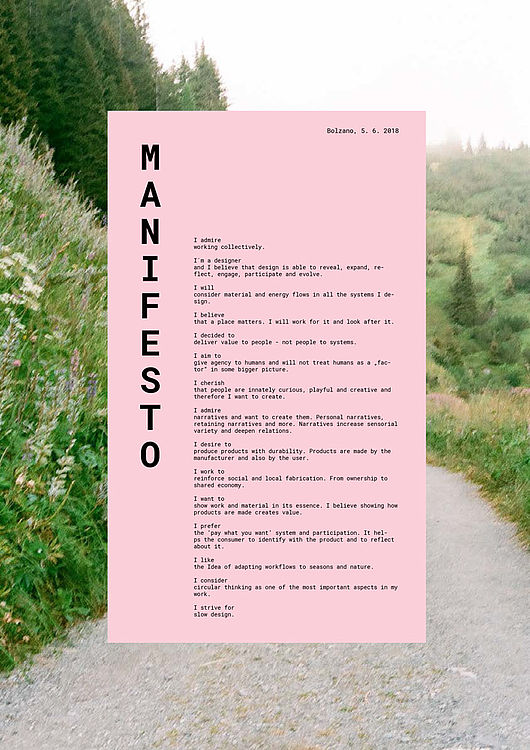

Im Zuge der Auseinandersetzung entstanden Manifeste, die einen klaren Standpunkt zum Thema Nachhaltigkeit beziehen.

In Zusammenarbeit mit Conrad Dorer, Umweltbundesamt

Production processes often follow straight value chains. This results in unwanted side streams and by-products – mostly waste products. We set ourselves the task of finding extraordinary, surprising, perhaps bizarre, but in any case, valuable, industrial waste streams and used them as a starting point – as raw materials for a new material, a new product, a system that works circularly instead of linearly. The project focused on the explorative and experimental examination of diverse materials and their further processing as well as the networking of different industries and processes for the development of sustainable product and business concepts. With the support of external partners, concepts, materials, services and application scenarios for waste materials were developed that cross-link and circulate. In the course of the discussion, manifestos arose which take a clear stand on the subject of sustainability.

In cooperation with Conrad Dorer, Federal Environment Agency

Participants and Projects:

Leopold Seiler: Your Hair - Your Ink – coloured ink made from your own hair

Ulrike Silz: materealise – materials from reused cotton fibres

Tian Pan: Garnet Sand 3+ – tiles and vessels

Jakob Müller: second skin – 3D printing or moulding with by-products of the leather industry

Lukas Keller: Baker’s Butchery – from industrial bread remains to mealworm protein

Fabian Hütter: Membrane – three possible applications

Melissa Fröhle: Rewollte – a project for the appreciation of wool

Spray Packaging

The egg membrane encloses the egg white and protects it from microorganisms. We owe the long durability of eggs to the membrane. Its reuse as food packaging is therefore more than conclusive. With the help of sodium hydroxide, the protein chains can be dissolved and sprayed onto e.g. vegetables directly.

Shortlife Fashion

The dried membrane not only has an interesting material property for packaging, it also has a special aesthetic. If one covers a surface with it in the wet state, the membranes adhere to each other after they dry and create a kind of non-woven textile – a textile with a very special symbolism – especially striking for a wedding dress.

Compostable Plastic

By compression moulding the egg membrane without any adhesive agents, the proteins link to a compostable bioplastic – a translucent material that is an alternative to fossil-based plastics.

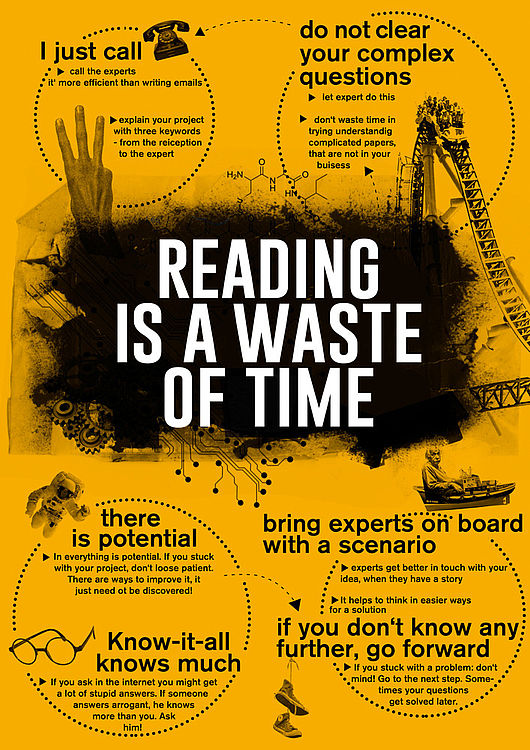

Manifesto by Fabian Hütter

second skin – 3D printing or moulding with by-products of the leather industry

by Jakob Müller

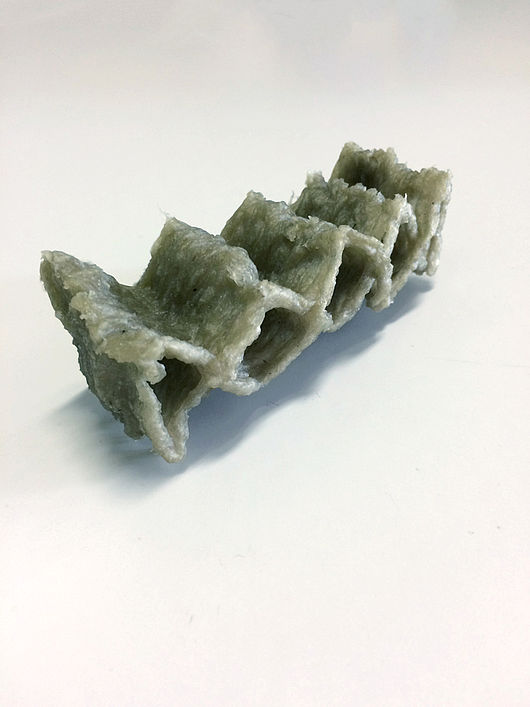

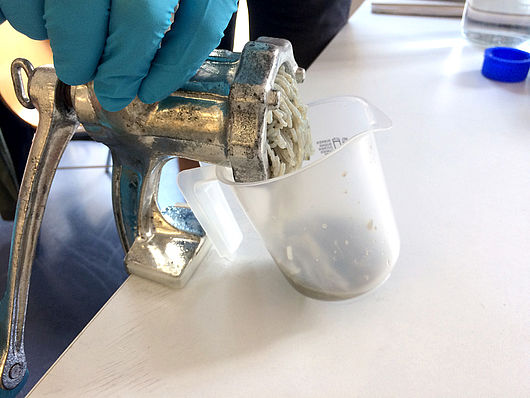

Second Skin is a material study that deals with the unused parts of skin in the tanning industry. Excess skin and its valuable ingredients usually stay unused and are disposed of. By chopping and homogenising the skin pieces, a viscous mass is produced. This can be shaped by 3D printing or injection moulding. The gluing properties of the skin create a sturdy, flexible material, which can be optimised for various applications with the aid of enzymes. These enzymes, such as transglutaminase, create cross-links within or between the proteins of the skin – similar to the tanning process of leather.

Injection moulding

The injection moulding process is attractive due to its cheap production of high volumes. However, the high shrinkage factor of the skin mass, the escaping water and high adhesion to various materials require a technical adaptation of standard injection moulding machines. As new paper injection moulding proves, these requirements for mould and machine can already be achieved by industry today.

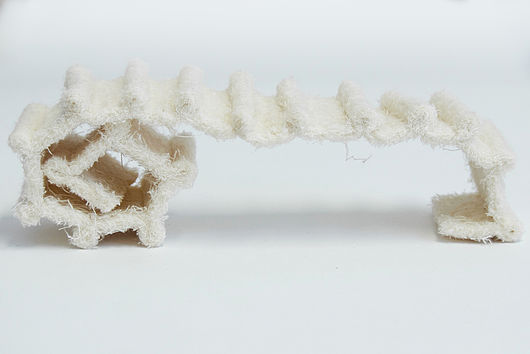

3D printing

To print the skin mass, a ceramic 3D printer is the best choice. They can print pasty masses thanks to a special extruder. Subsequently, the printed object must be dried in the oven.

The challenge is to give the skin mass a printable pasty consistency. By adjusting various parameters, such as humidity and the amount of enzyme, this can be regulated.

Transglutaminase catalyses the linkage of protein-bound glutamine and lysine sidechains and forms an isopeptide bond. This means that the collagen in the skin is cross-linked by transglutaminase. In order to test its effectiveness, samples were placed in water.

The material which is not crosslinked dissolved over time, while the one with the enzyme remained dimensionally stable.

Manifesto by Jakob Müller

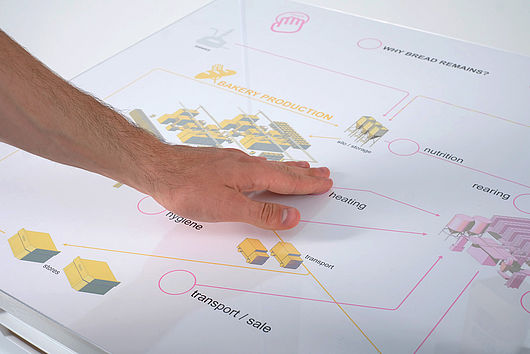

Baker‘s Butchery – from industrial bread remains to mealworm protein

by Lukas Keller

The concept Baker’s Butchery deals with the integration of a mealworm farm into a bakery, in which the overproduced bakery products get converted into protein. The integration leads to an efficient use of resources, due to multiple uses of infrastructure. The concept shows possibilities and advantages of a future in which insects are established as foodstuffs. It should help to question the existing food culture and production, which is a determining factor for global warming and the waste of resources. The Baker Chips are the communication medium and a possibility to approach insect consumption.

All calculations are based on an existing bakery taken as an example.

The Baker Chips are the prototype of a new product, that allows consumers to get used to the taste and consumption of mealworms. At the same time, it shows another possibility to convert overproduced bread into a new sustainable product.

The chips contain 85% wheat bread remains, 5% mealworm flour and 10% beetroot. The beetroot is responsible for the red colour but more importantly for the right moisture ratio to make a processable dough.

Interactive installation showing the concept of the Baker‘s Butchery

Manifesto by Lukas Müller

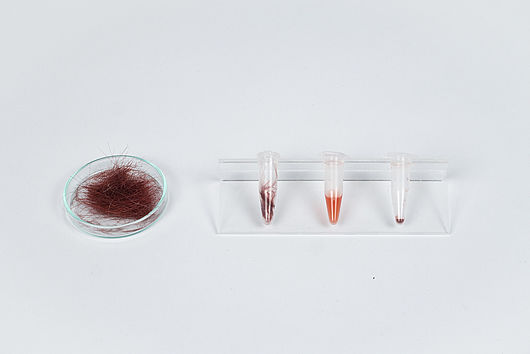

Your Hair - Your Ink – coloured ink made from your own hair

by Leopold Seiler

Our hair is unique and individual. It reveals who we are, stores habits and indicates our age. An ink from one’s own hair reveals personal uniqueness to the user and puts the great diversity that exists in hair into a different context – by making it tangible. A signature with this ink reveals more than just the name. It verifies itself unmistakably and every handwritten sentence contains a very personal quality. The personal relationship to the ink underlines the gesture of writing.

In cooperation with the Institute of Biochemistry of the Martin-Luther-University I have enzymatically dissolved various hairs, obtained pigments from them and then transferred these into ink.

Manifesto by Leopold Seiler

materealise – materials from reused cotton fibres

by Ulrike Silz

The project materialise aims to tackle the negative impact of the textile industry by reusing and recycling cotton fibres from production waste streams. It is time to realise that those fibres are a valuable material source and that adequate recycling systems need to be initiated. New technologies can convert the waste into materials like fibreboards, fleeces and cords. The possibilities in their handling and aesthetic potential are shown in a collection of experimental samples and material combinations. The application in seasonal fashion is exemplified by simple shoe components.

Manifesto by Ulrike Silz

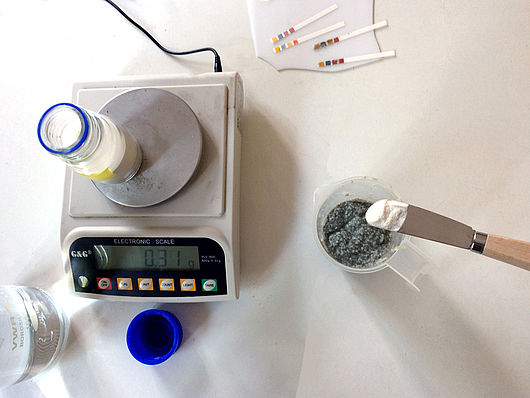

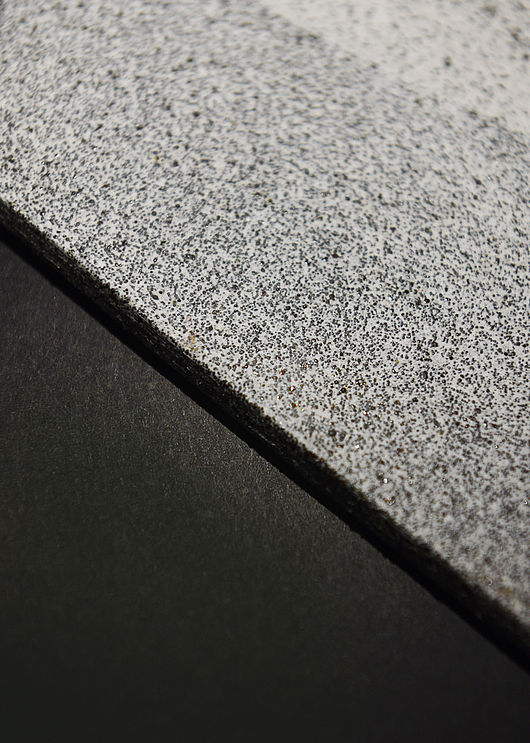

Garnet Sand 3+ – tiles and vessels

by Tian Pan

How can we use the large amount of shapeless waste sands, containing different particles of the cutting materials, which come from a normal water jet cutting factory? Through experiments with porcelain, glass and the simulation of the sinking process I found out that those waste sands could be suitable in the porcelain industry. It can be added to the traditional porcelain-making process to make everyday vessels. Another characteristic of this mixture is the anti-slip property, which is very well suited as an additive in tiles for floors in sanitary areas. On walls, the metallic property can be used as a magnetic pinboard.

Manifesto by Tian Pan

Rewollte – a project for the appreciation of wool

by Melissa Fröhle

This project focuses on redefining the value of mountain sheep wool in South Tyrol. Rewollte strengthens the authenticity of South Tyrolean sheep’s wool in properties, variety and almost forgotten applications, thereby creating a new perspective and appreciation for unused wool. The material properties can act as a mediator to the body. I intend to rediscover the traditional use of wool as a curative effect of skin to wool contact. Self-healing properties are activated. By using an application tool, an adapted jigsaw, people are able to customise the product in accordance with their body. For a better distribution and accessibility of this tool, fab labs are part of the project. Discover and experience the haptics of wool.

The project took place in collaboration with Theresa Bader, student at Free University Bozen, Italy

Pluto is a carpet, a blanket, a den, a partner, or whatever it is made into.

These prototypes are health-promoting body tools made of raw wool. The prototypes are supposed to relieve complaints for which raw wool has already been used in the past. All prototypes are realised with the adapted jigsaw tool.

The patch works against coughs when applied to one’s breast or against bruises on muscles.

A blackroll is a product from the occupational therapy and fitness sector. These are mainly made of plastic. Since there is a lot of body contact to the products, I see the needle felt with its properties optimally used here.

Manifesto by Melissa Fröhle

Publikation: dispose reuse recycle

hier bestellen >

mehr Informationen zum Projekt hier >

Publikation: dispose reuse recycle

hier bestellen >

mehr Informationen zum Projekt hier >